Robot supports production analysis at Trimet

Trimet Aluminium SE in Germany has expanded the analysis capacity of its test laboratory in Essen with new systems.

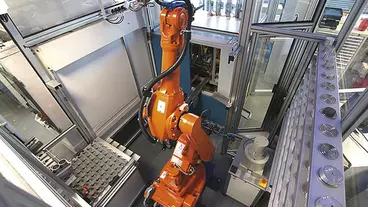

A 5-axis robot from ABB is automating the preparation of samples in various forms for spectral analysis. The system lightens the workload of employees, who can focus on evaluating data to guarantee the zero-defect policy of Trimet.

At Trimet’s spectral laboratory in Essen, around 350 to 400 electrolysis and foundry samples are analyzed every day. The company has purchased state-of-the-art equipment to process these quantities. The robot is connected to the laboratory’s pneumatic dispatch station. There it accepts the cartridges containing material samples, assigns the samples correctly and mills them in several stages to prepare their analysis. Flat, cylindrical and disc samples as well as grindings can be processed automatically. After the mandatory check for radioactivity, the elemental composition is determined.

This spectrometer process also runs automatically for many samples. In some cases, however, a human hand cannot be replaced in the lab, especially when it comes to safety-relevant parts used in the automotive industry. Spectral analysis specialists continue to evaluate the data for all samples. The robot ensures that laboratory staff members have the time they need to work intensively on data evaluation and to make sure that all analysis systems are always precisely calibrated.

Aluminium manufacturer Trimet has completed the expansion of its recycling plant in Gelsenkirchen and increased capacity by around 20%.

Interview with Trimet Executive Board member Dr. Andreas Lützerath about the future challenges in areas such as demographics, digitalization and decarbonization.

New heating concept tested successfully – nEXT4.0 digitalisation system offers better know-how transfer from the equipment manufacturer to the operator – new power electronics in induction furnaces