New LCA: carbon footprint of can production 40 % down

A new Life Cycle Assessment (LCA) shows that the carbon footprint of aluminium cans produced in North America has been significantly reduced over the last three decades.

The Life Cycle Assessment of North American Aluminium Cans report by sustainability consultancy Sphera shows that the carbon footprint of aluminium cans produced in North America has dropped by more than 40 % since 1991, and by 7 % since 2012. Energy demand has declined by similar levels during this period.

These reductions have been driven largely by decreased carbon intensity of primary aluminium production in North America, lighter cans (which are 27 % lighter per fluid ounce compared to 1991) and more efficient manufacturing operations.

“We’re proud of the continued efforts of the entire aluminium supply chain to make cans as sustainably as possible,” said Raphael Thevenin, vice-president of Sales and Marketing at Constellium and chairman of the Aluminum Association’s Can Sheet Producers Committee, which commissioned the study. “Aluminium cans are the most recycled beverage containers, with the best average recycled content, even though the recycling rate in the US needs improvement. As we continue to find ways to manufacture more efficiently, we are in the right path to further improve the carbon footprint of aluminium cans.”

LCA: lower carbon footprint of aluminium cans thanks to hydropowered metal production

“Our analysis found that the environmental performance of aluminium cans has continued to improve in North America,” said Chris Kofler, technical director, Americas at Sphera. “We also determined that, sourcing of primary metal is a significant contributor to the product’s overall environmental footprint, even with the current high recycled content of aluminium cans.”

Raw material sourcing has a “significant impact” on the sustainability of aluminium can production, according to the study. For example, while primary aluminium sourced from Canada is made almost exclusively using renewable hydropower, Chinese primary aluminium is made largely with coal-generated power, making it far more carbon-intensive.

This difference in sourcing “can have a profound impact” and “not all primary aluminium is created equal,” according to the report, which compared cans made in North America with hypothetical cans made using Canadian, Chinese or Middle Eastern primary aluminium. Even assuming 73 % recycled content, a can made with primary aluminium sourced in China would be almost twice as carbon-intensive compared to the average North American can, which uses a mixture of primary metal sourced domestically and from several other countries. Notably, an aluminium can made with only Chinese primary metal and no recycled content would be at least four times as carbon-intensive (cradle-to-gate) compared to a typical North American aluminium can.

Increasing use of recycled material reduces carbon intensity

Improving recycling rates and increasing the use of recycled material in production could improve the environmental performance of aluminium cans even further. Each percentage increase in the end-of-life recycling rate reduces the carbon intensity of aluminium can production (cradle-to-grave) by 1.02 kg CO2 equivalent per 1,000 cans. And each percentage increase in recycled content reduces the carbon intensity of aluminium can production (cradle-to-gate) by 1.43 kg CO2 equivalent per 1,000 cans.

Recycling a single can saves 1.56 MJ of energy or 98.7 grams of CO2 equivalent. This means that recycling just a 12-pack of aluminium cans will save enough energy to power a typical passenger car for more than three miles. The energy saved by recycling 100 % of aluminium cans in the US could power more than four million homes for a full year. This underscores the critical need for increased aluminium can recycling, which has declined in the US in recent years.

“The results of this report again highlight how critical it is that we increase investment in recycling infrastructure in the United States,” said Tom Dobbins, president and CEO of the Aluminum Association. “We lose more than USD800m worth of aluminium cans to landfills each year – a tremendous loss for the economy and the environment.”

Hydro can now deliver Hydro Circal recycled aluminium with a documented carbon footprint of 1.9 kg of CO2e/kg aluminium, down from previous 2.3 kg of CO2e/kg.

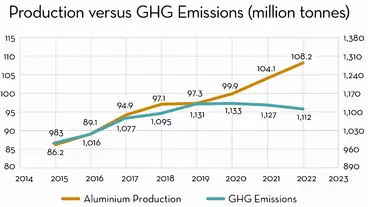

New data from the International Aluminium Institute (IAI) show that, for the first time, total greenhouse gas emissions from the global aluminium sector have not grown, even though aluminium production has shown an increase.

Vedanta Aluminium has announced the development of an innovative process to significantly reduce the generation of bauxite residue.