New, energy saving extrusion line for Spectra Aluminium

Spectra Aluminium has ordered a highly energy-saving extrusion press and gas-fired billet oven to be installed in Bradford, Ontario, Canada.

The 28-MN extrusion press from Danieli Breda is to process 8- to 9-inch aluminium billets. It will be equipped with Danieli’s patented energy saving solution (ESED 4.0), which allows energy savings of 25-30% on average compared to conventional systems available on the market. The press also features fully electric billet loading from the oven to the press, which drastically reduces heat/energy loss of the billets and improves their temperature accuracy. The automation system, also developed by Danieli, includes remote-controlled HMI via tablets.

<strong>Energy-saving aluminium billet oven

Danieli Breda’s ‘Ecoflame’ gas billet oven is designed to minimize heat loss from the exhaust fumes. The gas consumption per extruded tonne can be reduced by up to 30-35% depending on the product mix. The improved design of the burners and gas recirculation allows the production of billets up to 5,000 kg/h at 480 °C. Accurate temperature tapering is achieved through newly designed burners. The multivariable transducer controls correct gas and air mixtures, reducing maintenance and manual adjustments.

Commissioning of the extrusion line is scheduled for the second quarter of 2020.

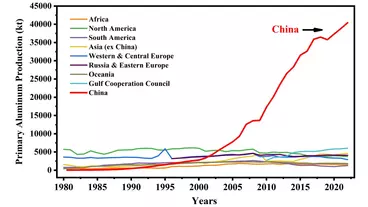

In the last decades, China’s annual output of primary aluminium has multiplied. At the same time, the country expanded on energy-saving and emission-reduction technologies.

Hertwich Engineering unveils a fully automated 3D inspection system for elevating the quality control of billet production.

Elval has placed an order with SMS Group for the delivery of its Viridis Energy & Sustainability Suite for its aluminium rolling mill in Oinofyta, Greece.