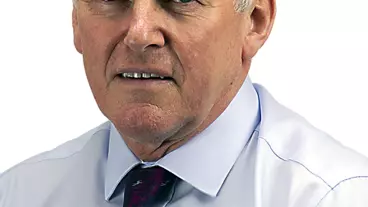

Peter Unwin becomes new Global Industry Manager Metals of Ametek Land and Ametek Surface Vision

Ametek Land and Ametek Surface Vision appoint Peter Unwin as Global Industry Manager – Metals. He will be responsible for both businesses and for the developing of their presence and performance in global metals manufacturing markets.

Following a successful period leading the metals industry segment for Ametek Land, a leading manufacturer of monitors and analysers for industrial infrared non-contact temperature measurement, combustion efficiency and environmental pollutant emissions, Peter is now be responsible for managing Ametek Surface Vision’s automated online surface inspection solutions for the aluminum, steel, and copper industries.

Peter’s extensive metals industry knowledge will be critical in driving change for all customer-facing processes and functions, while improving customer support around the world. Key focuses will include effective support for evolving quality standards and identifying changing customer needs that assist the development of AMETEK Land and Surface Vision product and application solutions.

Peter’s experience in the metals industry is guided by his experience as a Chartered Engineer, BSC (Hons) in Mechanical Engineering and MBA in Strategic Management. Prior to joining Ametek, he held positions as Head of Global Marketing Development at Sarclad Ltd, and as Sales Manager for Bronx Engineering and Parkgate Engineering.

“2020 undoubtedly presents new economic and political challenges, but what we can confidently predict is a growing emphasis on reducing waste and costs, and steadily increasing efforts to respond to environmental concerns around carbon emissions,” says Peter.

He continued, “Ametek Land’s measurement technologies offer a direct means of achieving these goals for a wide range of customer applications: a 5 percent energy saving can translate into significant cost efficiencies and environmental benefits. For example, our application solution for reheat furnaces combines the benefits of both our temperature monitoring and combustion efficiency solutions, resulting in measurable cost savings and better supported emissions targets.”

“These same drivers are in play for the surface inspection market: inspection points have been moving upstream from solely final inspection to installation on process lines such as galvanizing, annealing, and pickling. If a plant’s system can identify problems at the hot mill or pickling line, the additional waste created through unnecessary processing has consequent impacts on reducing waste and saving energy. Realizing these additional benefits will be a core driver for the AMETEK Surface Vision business in 2020.”

Promex Cyrus enhances aluminium surface inspection with AI and machine vision technologies.

Walther Trowal displays its equipment for finishing the surfaces of general and high-value components at the ‘Mach 2024’ exhibition.

Sustainability is one of the core values at EGA, with three pillars: safeguarding the environment, social responsibility and good governance.