Otto Junker supplies largest furnace for ingots

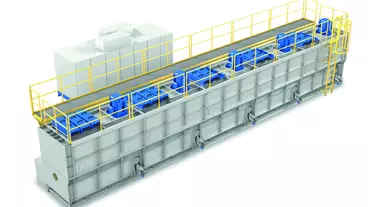

Otto Junker GmbH handed over a new ingot furnace to Logan Aluminium Inc. in Russellville, Kentucky in 2019.

The furnace for heating and homogenizing aluminium ingots is the largest one Otto Junker has supplied in its entire history.

Logan Aluminium is one of the world’s leading manufacturers of flat-rolled aluminium sheet, a product that is primarily destined for use in the beverage market. To expand production, the company had ordered the new furnace, which impresses with its capacity. The gas-fired furnace is dimensioned to simultaneously hold 32 ingots, each weighing up to 32 t, resulting in a charge weight of over 1,000 t. Apart from the furnace with active cooling system, the scope of delivery also included machinery for charging and discharging the ingots, as well as a gantry crane and a mobile roller table as a connection to the existing rolling mill feed table.

<strong>Furnace convinces by temperature uniformity and low energy consumption

The furnace is highly efficient when it comes to even temperature distribution, energy consumption and automation. High convection technology ensures fast heating and cooling with short cycle times and low energy consumption.

Otto Junker’s skid system integrated into this furnace has been tried and tested over many years and is virtually maintenance-free. Used to transport the ingots one by one through the furnace, it is made of a number of cast parts manufactured in the company’s own stainless steel foundry. During the earlier stages of the skid system development, the extensive expertise of the stainless steel foundry could already be drawn upon when selecting alloys.

With the successful completion of this order, Otto Junker has demonstrated that its pusher furnace technology is highly efficient in the largest class of this type of furnace.

Otto Junker presents a new preheater, EcoJet, which in combination with the induction furnace JuDy offers a forward-looking solution for metal processing.

Otto Junker presents a new preheater, EcoJet, which in combination with the induction furnace JuDy offers a forward-looking solution for metal processing.

Replacing a LPG furnace with a combination of an electric resistance furnace and an induction furnace improves energy efficiency and reduces CO2 emissions.