Optimized insulation in heat treatment plants

Aichelin Service GmbH has relined and optimized the insulation of two industrial furnaces at Daimler Truck AG.

The new brickwork for two industrial furnaces required due to wear provided an opportunity for Aichelin Service GmbH in late 2022 to fundamentally optimize the thermal insulation of the plants together with the customer. The company has successfully implemented similar projects in the past at the customer’s plant in Gaggenau, Germany. The current project revolved around new brickwork for the heat treatment plants of a different manufacturer.

Significant energy savings thanks to new brickwork

As a long-term partner, Aichelin Service has been supporting Daimler Truck AG continuously with regular maintenance and repair works, as well as in projects regarding plant modernization and optimization. In Gaggenau, there are numerous heat treatment plants by different manufacturers, among them several Aichelin plants. For the current project, the brickwork for a LOI Thermprocess plant needed to be renewed and optimized. The goal was to replace the entire brickwork in a rebuild time of only six weeks, including disassembly and reassembly, while increasing the energy efficiency of the plant and enabling significant energy savings. The result: Wall losses were reduced by 10-15 %. The optimized insulation thus contributes to higher energy efficiency.

Depending on the type and intensity of plant use, the thermal insulation and in particular the brickwork in industrial furnaces wears out after around 10 to 20 years and must be replaced entirely. The isothermal annealing system in question – a coherent, U-shaped installation consisting of one high-temperature and one low-temperature furnace – has been in use at the Gaggenau plant since 1971. The high-temperature furnace is gas-fired and achieves temperatures of up to 950 °C; the low-temperature furnace is operated with electric heating elements and reaches temperatures of up to 700 °C.

Additional customized optimizations

To increase energy efficiency, the brickwork of the two furnaces should not simply be replaced 1:1. In addition to the complete renewal of the brickwork, the wall structure was to be reinforced and thermally optimized. Moreover, further customer-specific energy optimizations had to be implemented. Temperature measurements on the systems before the start of the project provided additional indications of further optimization potential, including around insulation, the burner flanges, and the outlet and door openings.

Aichelin Service took over the complete project planning, coordination, and implementation as general contractor. The time constraints in this project were especially challenging, as a very narrow time window of only 30 working days including Saturday work had to be met. To achieve this, Aichelin Service successfully coordinated four project partners in order to perfectly align and execute the various works.

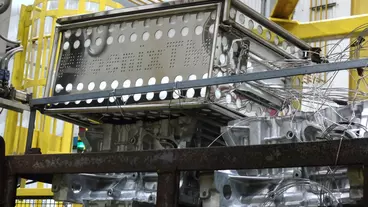

100 m3 of material installed

The project started in November 2022. After the dismantling of the heating elements by Daimler Truck employees, the excavation work as well as other preparatory work was carried out by Aichelin Service and its partners, such as the removal and reassembly of the burner flanges, welding work, weld seam tests, and more. This was followed by the new brickwork and the reassembly of the heating technology before the subsequent test run in cold operation. The brickwork with an optimized wall construction was carried out with a suitably strong service team, which put together over 100 m3 of material ‘brick on brick’. In total, around 20 workers from the various partners, as well as the project managers and coordinators from Aichelin Service and the customer, were deployed during the project. The final work was completed in December. The inspection and approval by the customer were carried out after the successful return to operation in late January 2023.

Thru-process monitoring solutions allow product temperature profiling of all the solutionising, water quench and age hardening phases.

Trimal-38 (AlSi8ZnMn) has the potential to reduce energy demand and to increase cost efficiency by avoiding heat treatment after casting.

Reimann, Mönchengladbach, will be presenting pioneering solutions for industrial furnace refurbishment at ALUMINIUM 2024.