LOI Thermprocess partner of Audi-Technikum

On November 22, the German carmaker Audi inaugurated its Technikum in Neckarsulm, Germany. The

materials technology centre is equipped with a pioneering heat treatment plant of Tenova LOI Thermprocess.

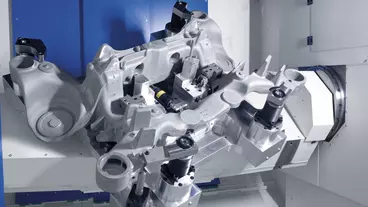

The Audi materials technology centre with its innovative plant technology enabled the creation of optimal preconditions to develop lightweight materials and highly economic manufacturing processes for future light metal construction parts. Tenova LOI Thermprocess is both development partner and supplier of the state-of-the-art heat treatment plant.

For many years, a development cooperation in the field of tempering structural cast components exists between the two companies. The modular design of the new heat treatment plant was jointly developed according to Audi specifications. This plant consists of a furnace for solution annealing and aging treatment, a fluidized bed furnace and a quenching device that can be operated with air or water.

“The Tenova LOI heat treatment plant represents an important section in the Audi-Technikum since it is responsible for ensuring the crucial mechanical properties (stability, ductility) of the products”, said Erik Micek, CEO of Tenova LOI Thermprocess GmbH. “We are particularly proud of cooperating with Audi to develop highly flexible process designs that allow Audi to carry out investigations in multiple directions”.

The newly developed quenching device represents a novelty with the achievable range of cooling gradients. It is a beneficial precondition for Audi in Neckarsulm to develop in detail new parts of different manufacturing processes and alloys which prove to be suitable for later series production.

“The material development represents the basis for the successful light-weight chassis construction in the Audi works in Neckarsulm. The innovative materials increase the efficiency of our models and are thus an essential components towards electromobility”, explains Helmut Stettner, plant manager at the Audi site Neckarsulm.

Both partners continue elaborating further trend-setting solutions with the aim to optimize the process guidance and the component properties in the production of lightweight construction parts.

When a sports car manufacturer was running short on structural parts, it put its trust in the process expertise of the mechanical engineers at August Wenzler Maschinenbau in Spaichingen, Germany.

A smart foundry was set up at Purdue Polytechnic in collaboration with Sinto America for students to learn metalcasting processes and technologies.

Constellium has signed a partnership agreement with PyroGenesis Canada Inc. to test the use of plasma torch technology at an industrial scale.