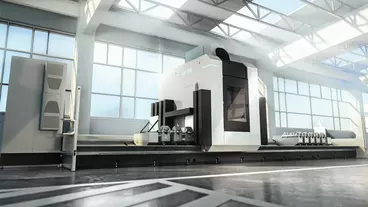

Flexible machining with the Schüco AF 510

The Schüco AF 510 CNC machine is particularly flexible when it comes to machining aluminium window, door, façade and special profiles.

The new Schüco AF 510 CNC machine builds on the Schüco AF 500, offering new technology and increased performance for efficient and precise six-sided processing. The highly dynamic five-axis machine features improved spindle performance of 22 kW, integrated vibration monitoring and clamps with decentralised operation. This processing centre therefore provides an efficient and flexible foundation for practically any metal fabrication task.

Precise six-sided processing

Milling, cutting, and notching are all possible with just one machine: the new Schüco AF 510 processing centre. The core of the CNC machine is the high-performance, 22 kW spindle in conjunction with a new spindle cooling system. Together with the integrated vibration monitoring, the processing centre enables preventative maintenance to be carried out and paves the way towards Industry 4.0. At the request of the metal fabrication companies, which contributed important practical experience to the development of the machine, the new CNC machine also features a hinge conveyor belt and oil mist extraction system. Clamps with decentralised operation further support efficient fabrication. They allow for simultaneous processing with a feed rate of up to 25 m/min. Automatic pressure monitoring in the clamping devices accelerates the start of the process. Alternating operation mode also allows both sides of the machine to be used in parallel. Automatic positioning of the clamps and easy insertion of the profiles simplify operation for fast and efficient fabrication.

Flexibility and efficiency combined

The Schüco AF 510 CNC machine is particularly flexible when it comes to machining aluminium window, door, façade and special profiles. Thanks to the powerful drive and motor technology, the machine can efficiently process even larger profile cross sections. The absolute position-measuring systems in all six axes mean the axes no longer need to be referenced. In addition, the perfectly balanced machine configuration enables notching from below and processing close to the clamping device. The Schüco AF 510 processing centre is also visually impressive, with a modern design including an LED status display. Robust, durable safety bumpers with leather covers add a finishing touch to the machine. Like the Schüco AF 500 CNC machine, the AF 510 can be combined with the RX LOAD 500 fabrication robot, which was developed together with Kuka for autonomous loading and unloading. The AF 510 processing centre and the robot cell can be seen in action in the glazed Fabrication Showroom in the new Schüco Welcome Forum.

With the horizontal machining centre Aerocell 160 and high-volume tools, Bavius and Mapal provide users with a combination that takes machining aluminium structural parts to a new level.

The machining of aluminium for components in electric vehicles is challenging. Innovative solutions and tools are required to meet the industry’s standards.

Investment in state-of-the-art equipment for processing large-scale aviation components